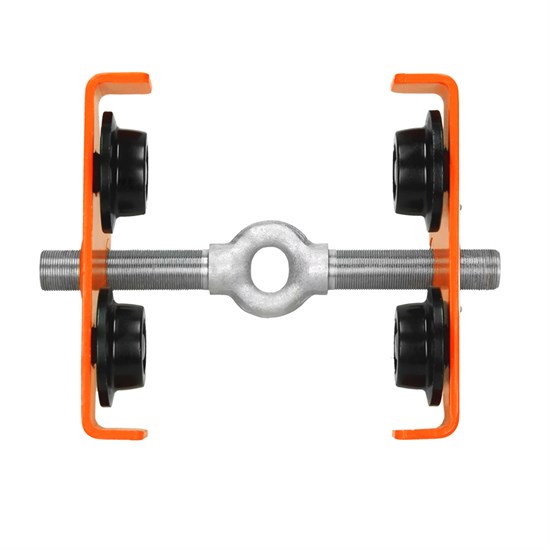

Trolley Rolling trolley 0,5 ton 50-220 mm

- Practical trolley

- Works straight or curved tracks

- Ideal material handling tool

- Wide range of applications

- Quality from ECD Germany

- Stable design

- Robust

- 3 years warranty

Description:

The trolley is used for precise positioning and easy moving of larger loads by means of a manual or electric hoist. The 0.5 ton trolley is adjustable for standard or wide flange I-Beam rails. It is designed to be attached to the flange of steel girders or gantry cranes to serve as an attachment point for chain hoists and hoisting equipment.

The double wheels are designed for a straight or conical support rail and work on both straight and curved rails. Heavy-duty construction, stable rollers (ball bearing mounted) and a simple width adjustment to the iron beam by means of a counter-rotating fine thread for exact adjustment are the features of this running gear. With its durable powder coating and lubricated sealed bearings, it is an ideal material handling tool for warehouses, garages and other industrial applications.

Features:

Safe stand due to its high dead weight.

It is an ideal material handling tool for warehouses, garages and other industrial areas.

Adjustable for a wide range of beams and different profiles. The rollers are designed for a maximum beam flange inclination of 14

Adjustable for standard or wide flange I-beam rail

Easy adjustment to flange width via the axis

Centered suspension eye

Robust, stable design

Easy and effortless handling

Works on straight or curved tracks

Safe working load for 0.5 tons

Cue:

As an attachment point for a chain hoist or other hoisting equipment. For mounting on a carrier. (Please check load capacity / static load!)

Scope of delivery:

1 x 0,5 T trolley Rolling trolley

The trolley is used for precise positioning and easy moving of larger loads by means of a manual or electric hoist. The 0.5 ton trolley is adjustable for standard or wide flange I-Beam rails. It is designed to be attached to the flange of steel girders or gantry cranes to serve as an attachment point for chain hoists and hoisting equipment.

The double wheels are designed for a straight or conical support rail and work on both straight and curved rails. Heavy-duty construction, stable rollers (ball bearing mounted) and a simple width adjustment to the iron beam by means of a counter-rotating fine thread for exact adjustment are the features of this running gear. With its durable powder coating and lubricated sealed bearings, it is an ideal material handling tool for warehouses, garages and other industrial applications.

Features:

Safe stand due to its high dead weight.

It is an ideal material handling tool for warehouses, garages and other industrial areas.

Adjustable for a wide range of beams and different profiles. The rollers are designed for a maximum beam flange inclination of 14

Adjustable for standard or wide flange I-beam rail

Easy adjustment to flange width via the axis

Centered suspension eye

Robust, stable design

Easy and effortless handling

Works on straight or curved tracks

Safe working load for 0.5 tons

Cue:

As an attachment point for a chain hoist or other hoisting equipment. For mounting on a carrier. (Please check load capacity / static load!)

Scope of delivery:

1 x 0,5 T trolley Rolling trolley

Technical information:

Max. Load capacity: approx. 500 kg (0.5 T)

Min. turning radius : approx. 0.9 m

Weight: approx. 5.5 kg

Max. Load capacity: approx. 500 kg (0.5 T)

Min. turning radius : approx. 0.9 m

Weight: approx. 5.5 kg

Technical details:

Max. load capacity: approx. 500 kg (0,5 T)

Min. turning radius: approx. 0,9 m

Weight: approx. 5,5 kg

Max. load capacity: approx. 500 kg (0,5 T)

Min. turning radius: approx. 0,9 m

Weight: approx. 5,5 kg

|

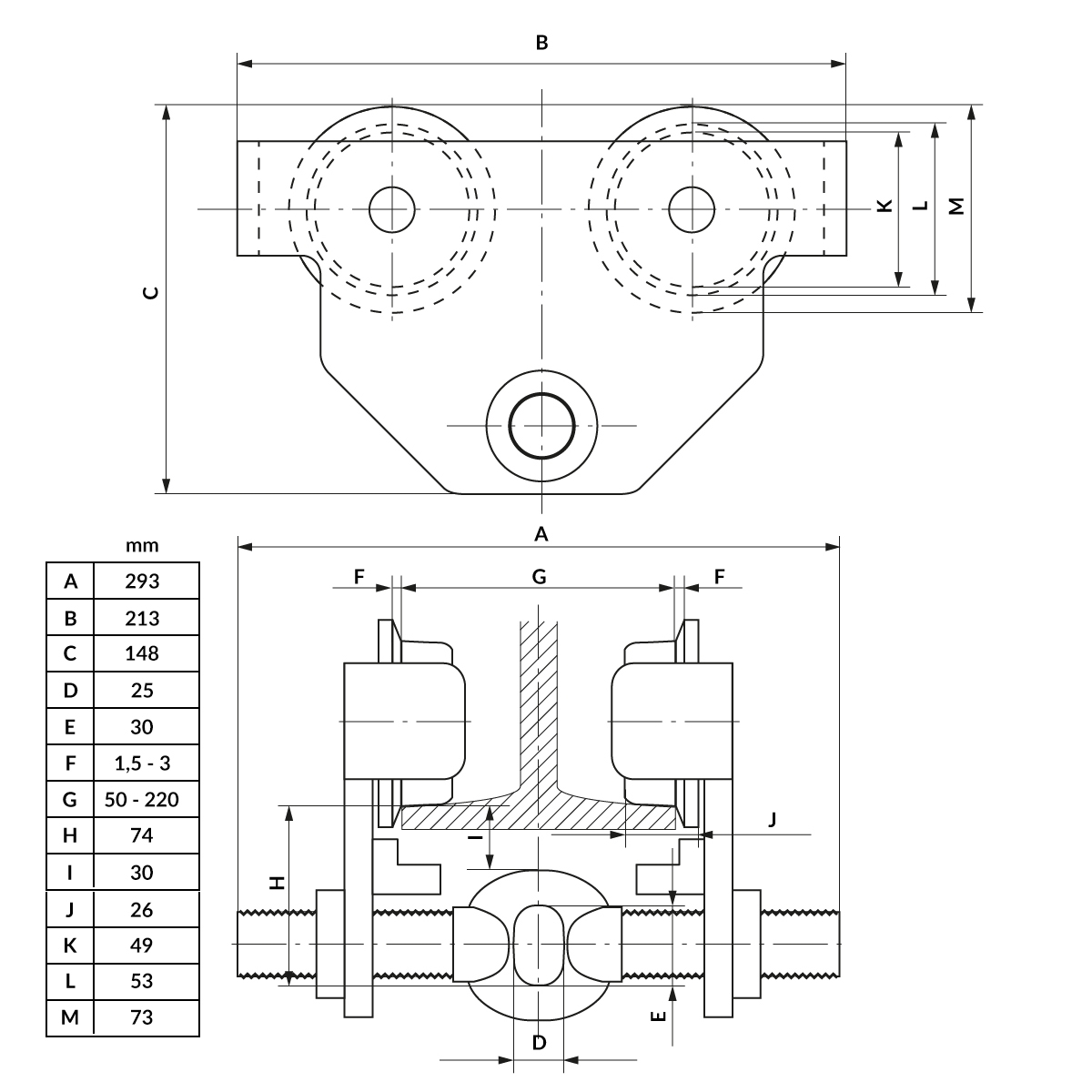

| Numbers | Name | Dimensions |

| A | Overall length | approx. 293 mm |

| B | Overall width | approx. 213 mm |

| C | Total height | approx. 148 mm |

| D | Min. diameter of the hanger | approx. 25 mm |

| E | Max. diameter of the hanger | approx. 30 mm |

| F | Width of the slope on the roller from the pad to the edge | approx. 1,5 - 3 mm |

| G | Flange width | approx. 50 - 220 mm |

| H | Lower edge of the inner diameter from the hanger to the lower edge of the rollers | approx. 74 mm |

| I | Distance upper edge of the hanger to the lower edge of the roller | approx. 30 mm |

| J | Roll width | approx. 26 mm |

| K | Min. diameter of the roll inside | approx. 49 mm |

| L | Max. diameter of the roll inside | approx. 53 mm |

| M | Diameter with roll edge | approx. 73 mm |

Real ratings